The Essential Guide to Understanding Knife Gate Valve Function

What is the function of a knife gate valve?

A knife gate valve is a critical component in many industrial applications, providing a dependable and efficient method of controlling the flow of diverse fluids. As the name implies, this valve uses a sharp-edged gate to cut through the media and control its flow. A knife gate valve’s principal role is to produce a tight shut-off, stopping media passage while closed but allowing unrestricted flow when open.

The ability of a knife gate valve to handle thick and viscous media, like slurry, pulp, or wastewater containing solids, is one of its main advantages. The valve’s construction allows the gate to slice through the media, removing any possible blockages or clogs in the process. Applications in mining, pulp and paper, wastewater treatment, and chemical processing are especially well-suited for knife gate valves.

Components and design of a knife gate valve

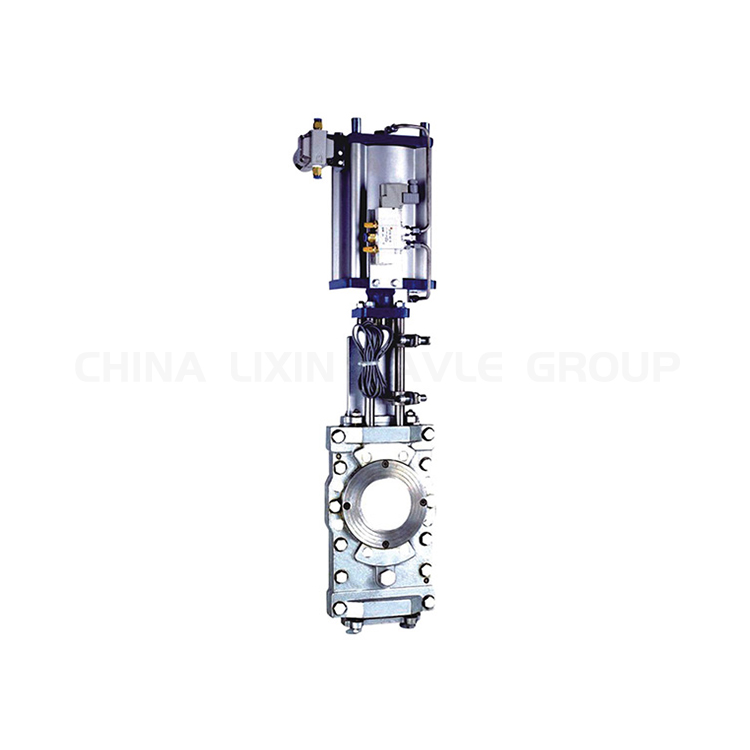

You should familiarize yourself with the parts and design of a knife gate valve in order to fully comprehend how it operates. The actuator, packing gland, gate, and body are the main components of a standard knife gate valve.

The bodies of knife gate valves are often built of durable materials like carbon steel, cast iron, or stainless steel, depending on the specific needs of the application. The gate, which is primarily in charge of regulating the flow, is often constructed out of stainless steel or another durable material. The sharp edge of the valve punctures the media when it is opened or closed.

The actuator is the mechanism that operates the valve, allowing it to be manually or automatically controlled. The most common types of actuators used in knife gate valves are handwheels, levers, pneumatic cylinders, and electric motors. Finally, the packing gland ensures a tight seal around the gate, preventing any leakage when the valve is closed.

Advantages and disadvantages of knife gate valves

Knife gate valves have pros and cons of their own, just like any other industrial component. Knowing these might assist you in deciding if a knife gate valve is the best option for your particular application.

Knife gate valves’ capacity to handle high-density media including solids is one of their main advantages. The gate’s sharp edge slices through the media to avoid any obstructions or clogging. Knife gate valves are therefore perfect for use in sectors like mining and wastewater treatment where particles are frequently present.

Another advantage of knife gate valves is their compact design. Unlike other types of valves, knife gate valves require minimal space for installation and operation. This makes them suitable for applications where space is limited or where a smaller footprint is desired.

However, it is important to consider the disadvantages of knife gate valves as well. One potential drawback is their limited ability to regulate flow. Knife gate valves are primarily designed for on-off applications and may not provide precise flow control in situations where a gradual or throttling control is required.

Knife gate valves might also not be appropriate for uses requiring a high degree of sealing. Knife gate valves offer a tight shut-off, although they might not be as good at stopping leaks as other valve types, such globe valves.

Popular manufacturers of knife gate valves

Choosing a knife gate valve from a reputed manufacturer that makes high-quality valves is essential when choosing one for your particular application. The following well-known producers of dependable knife gate valves are well-known:

- Lixin Valve: Specialized in producing knife gate valves, Lixin Valve provides a broad selection of choices to accommodate different industrial needs. Their abrasive media-handling valves are renowned for their exceptional performance, robustness, and dependability.

- Bray Controls: A manufacturer of industrial valves. In order to satisfy the strict demands of various industries, they provide a wide range of valves.

- DeZURIK: Known for their high-quality and innovative products, DeZURIK is a reputable name in the valve business. In order to effectively control flow in difficult situations, they provide a variety of knife gate valves.

By choosing a knife gate valve from a reputable manufacturer, you can be sure that the valve will meet your specific requirements and be strong and effective.

Frequently Asked Questions(FAQ)

Q: Can a knife gate valve handle corrosive media?

A: Yes, knife gate valves can be manufactured from materials that are resistant to corrosion, such as stainless steel or special alloys. However, it is crucial to select the appropriate material based on the specific corrosive properties of the media in your application.

Q: Are knife gate valves suitable for high-pressure applications?

A: Knife gate valves are generally not recommended for high-pressure applications. Their design and sealing mechanism may not be able to withstand the high pressures associated with certain industrial processes. It is advisable to consult with a valve expert to determine the most suitable valve type for your high-pressure application.

Q: How do I choose the right size of knife gate valve?

A: The size of a knife gate valve should be selected based on the flow rate and pipe size of your application. It is essential to consider factors such as the media characteristics, pressure requirements, and system design when determining the appropriate valve size. Consulting with a valve manufacturer or expert can help you make an informed decision.

Q: Can knife gate valves be automated?

A: Yes, knife gate valves can be automated using various types of actuators, such as pneumatic cylinders or electric motors. Automating a knife gate valve can provide improved efficiency and control, particularly in applications where frequent opening and closing of the valve is required.

In conclusion, everybody working in an industry that depends on effective media flow management has to understand how a knife gate valve works. You can choose the best gate valve for your application by being knowledgeable about the parts and construction of knife gate valves, as well as the benefits and drawbacks of each. To guarantee the dependability and functionality of your knife gate valve, be sure to select a reliable manufacturer, like Lixin Valve.