Technical Specifications

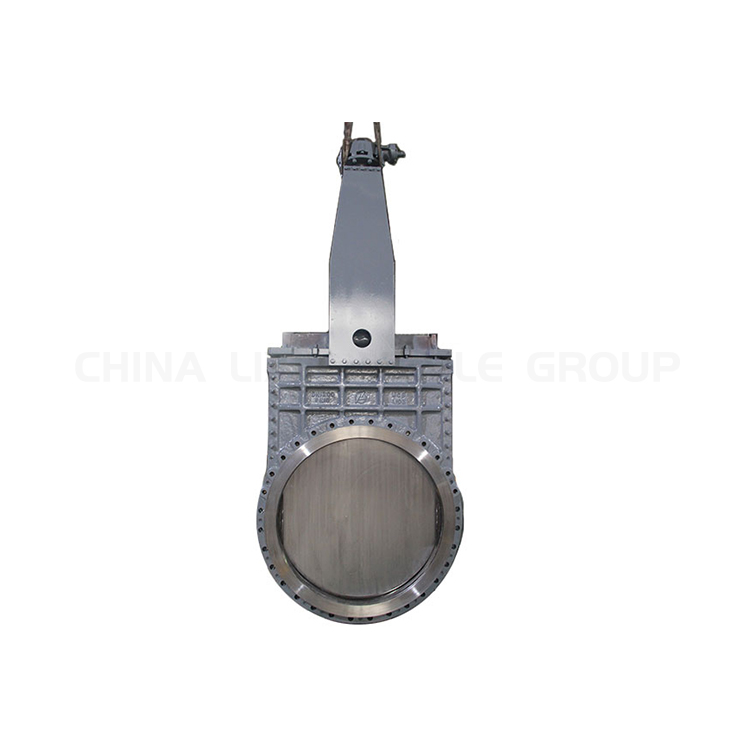

| Size Range NPS2″-56″/DN50-1400mm | Main Material Carbon steel, Stainless Steel, Aluminum Bronze, Duplex steel etc.

(Other materials are available under request.) |

| Temperature Rating Soft Seat: -40 ~ +120°C | Stem material Stainless steel |

| Pressure Rating I.0Mpa 1.6Mpa 150LB | Directional /Stem Type Bi-directional/Rising Stem |

| leakage level Soft seat:Zero Leakage | Body Style Wafer |

| Disc Material Stainless steel, Duplex steel etc. | Flange Drilling ASME B16.5, EN1092, BS etc. |

| Seat Material Soft Seat: NBR, EPDM, NR etc. | Port Type Reduce Port |

| Design Standard MFR Standard | Test Standard MFR Standard |

| Face to Face MFR Standard | Operation Handwheel, Worm Gear, Electric, Pneumatic, etc. |

| Application Power, Mining, Pulp & Paper, Cement, Carbon Black, Chemical,Wastewater |

| Other The carefully selected materials and contemporary design make our knife gate valve highly recognized. If our knife valve cannot meet your choice, we can provide you with special made. |

Chief Features

Ultra-thin design, beautiful appearance, light weight and compact structure, easy to install and use.

The valve is connected by clip-on, and the structure length is short, which can reduce the weight of the entire pipeline system.

The bottom of the gate is smooth without any grooves to ensure that impurities do not accumulate.

The U-shaped sealing strip valve body is inlaid structure, which can prevent leakage caused by the movement of the sealing strip, so that the slurry valve can achieve two-way zero leakage sealing.

The bottom of the valve plate is a semi-circular arc, and after the valve is opened, it is a full flow channel.

No valve cavity structure, the medium will not accumulate.