Today, all industries are actively seeking solutions to reduce emissions and increase sustainability. In the field of industrial processes, the application of valves has become an important area of innovation. In particular, low emission valves, such as gate and ball valves, have become a key solution for minimizing disorganized emissions and improving environmental performance. In this article, we will give an in-depth look at low emission gate valves in terms of their application, advantages, and discuss their role in sustainable development.

What are Low Emission Valves?

Low emission valves are made to lower fugitive emissions from industrial operations. They minimize leakage from valves during switching and regular operation and optimize sealing performance to effectively limit emissions of greenhouse gases and volatile organic compounds (VOCs). Low emission valves maintain superior sealing performance in corrosive environments, high pressure, and temperatures by utilizing cutting-edge sealing technologies and materials such as bellows seals, packing seals, and unique metal alloys. Selecting low emission valves benefits businesses in both the short and long term by lowering energy usage and increasing production while also assisting in meeting ever stricter environmental laws.

Types of Low Emission Valves

Low emission gate valves and low emission ball valves are two common types of low emission valves:

Low Emission Gate Valves

Special sealing design is adopted to effectively reduce the leakage at the stem packing. Its structure is sturdy and durable, suitable for high pressure and high temperature working conditions. In petrochemical, natural gas and other industries, low emission gate valves can effectively control VOCs emissions to ensure personnel safety and environmental cleanliness.

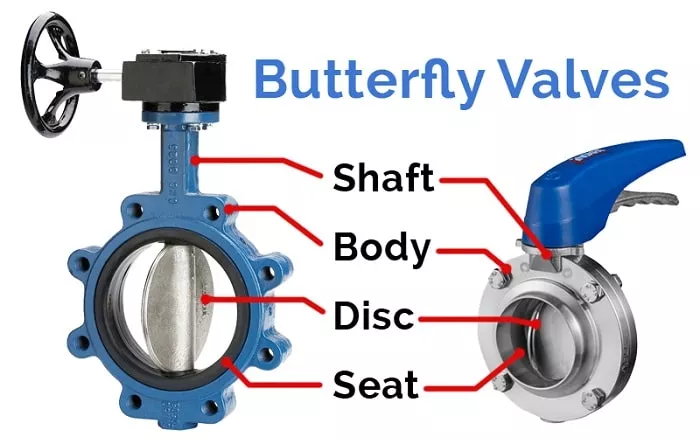

Low Emission Ball Valves

Known for its excellent sealing performance. The precision fit between its ball and seat virtually eliminates the possibility of leakage. The ease of operation and rapid opening and closing also make it the first choice in many industrial scenarios. Low emission ball valves are widely used in chemical, pharmaceutical, food processing and other fields to realize green production.

Choosing low emission valves is not only to fulfill the responsibility of environmental protection, but also a wise move to enhance corporate image and reduce operating costs.

What is Low Emission Gate Valves Used For?

Low emission gate valves are utilized in a wide range of applications where reliable shut-off and minimal emissions are paramount. Some common uses include:

Flow control in pipelines for oil, gas, and water transportation.

Isolation and regulation of fluids in refineries, chemical plants, and power generation facilities.

Process control in industries requiring precise fluid management, such as pharmaceutical manufacturing.

Advantages of Low Emission Gate Valves

The advantages of low emission gate valves are mainly reflected in the following aspects:

| Advantage | Description |

|---|---|

| Significantly reduce fugitive emissions | Low emission gate valves utilize advanced sealing technology to minimize leakage, helping meet strict emission standards and reduce environmental pollution. |

| Improve safety | By reducing the risk of leakage, low emission gate valves enhance the safety of the production process and protect employee health. |

| Reduce operating costs | They help decrease unorganized emissions, conserve resources, lower energy consumption, and improve overall operational efficiency. |

| Comply with environmental regulations | Low emission gate valves meet stringent emission standards, ensuring compliance with evolving environmental regulations and avoiding fines. |

| Improve corporate image | Their use demonstrates a commitment to environmental responsibility, enhancing the company's reputation and creating additional business opportunities. |

Significantly reduce fugitive emissions: Traditional gate valves often cannot be completely sealed when closed, resulting in gas leakage, environmental pollution and resource waste. Low emission gate valves use advanced sealing technology to effectively reduce leakage, meet strict emission standards, and create a cleaner production environment for enterprises.

Improve safety: Unorganized emissions not only pollute the environment, but may also cause safety hazards. Low emission gate valves improve the safety of the production process by reducing the risk of leakage, ensuring the health of employees and the stable operation of equipment.

Reduce operating costs: Leaking gas means wasted resources. Low emission gate valves can reduce unorganized emissions, reduce energy consumption, save operating costs, and improve economic benefits.

Comply with environmental regulations: As environmental regulations become increasingly stringent, low emission gate valves are a necessary condition to comply with regulations. Its excellent sealing performance can meet the most stringent emission standards, helping companies avoid fines and negative impacts due to illegal emissions.

Improve corporate image: Choosing low emission gate valves reflects the company's responsibility for environmental protection, helps improve the company's image, win social recognition, and gain more business opportunities.

Low Emission Gate Valves vs. Low Emission Ball Valves

Low emission gate valves or low emission ball valves, which is better for your application?

Here’s a comparison table for Low Emission Gate Valves vs. Low Emission Ball Valves:

| Feature | Low Emission Gate Valves | Low Emission Ball Valves |

|---|---|---|

| Flow Control | Provides linear flow control, ideal for precise adjustments. | Uses rotating sphere for on/off control, not ideal for precise flow control. |

| Leakage Rate | Excellent sealing, effectively reduces VOC emissions. | Effective sealing, but may not be as precise in reducing leakage as gate valves. |

| Temperature and Pressure Resistance | High temperature and high pressure resistant, suitable for harsh conditions. | Generally suited for lower pressure and temperature conditions. |

| Ease of Operation | Slower opening and closing speeds. | 90-degree rotation for quick opening and closing. |

| Fluid Resistance | Higher fluid resistance due to design, may reduce flow efficiency. | Low fluid resistance, improves flow efficiency and reduces energy consumption. |

| Maintenance | Simple construction, easy to maintain. | Generally more complex, may require more maintenance. |

| Size and Installation | Larger, takes up more space for installation. | Compact design, saves installation space. |

| Cost | More affordable. | Relatively more expensive. |

| Best Use Case | Chemical processes requiring precise flow control. | Oil and gas pipelines requiring quick on/off switching. |

Low Emission Gate Valves

Utilizes a wedge gate to provide linear flow control for scenarios where precise flow adjustment is required. Benefits include:

Low leakage rate: Excellent sealing and effective in reducing VOC emissions.

High Temperature and High Pressure Resistant: Suitable for harsh operating conditions.

Easy to maintain: Simple construction and easy maintenance.

The disadvantages of gate valves are higher fluid resistance and slower opening and closing speeds.

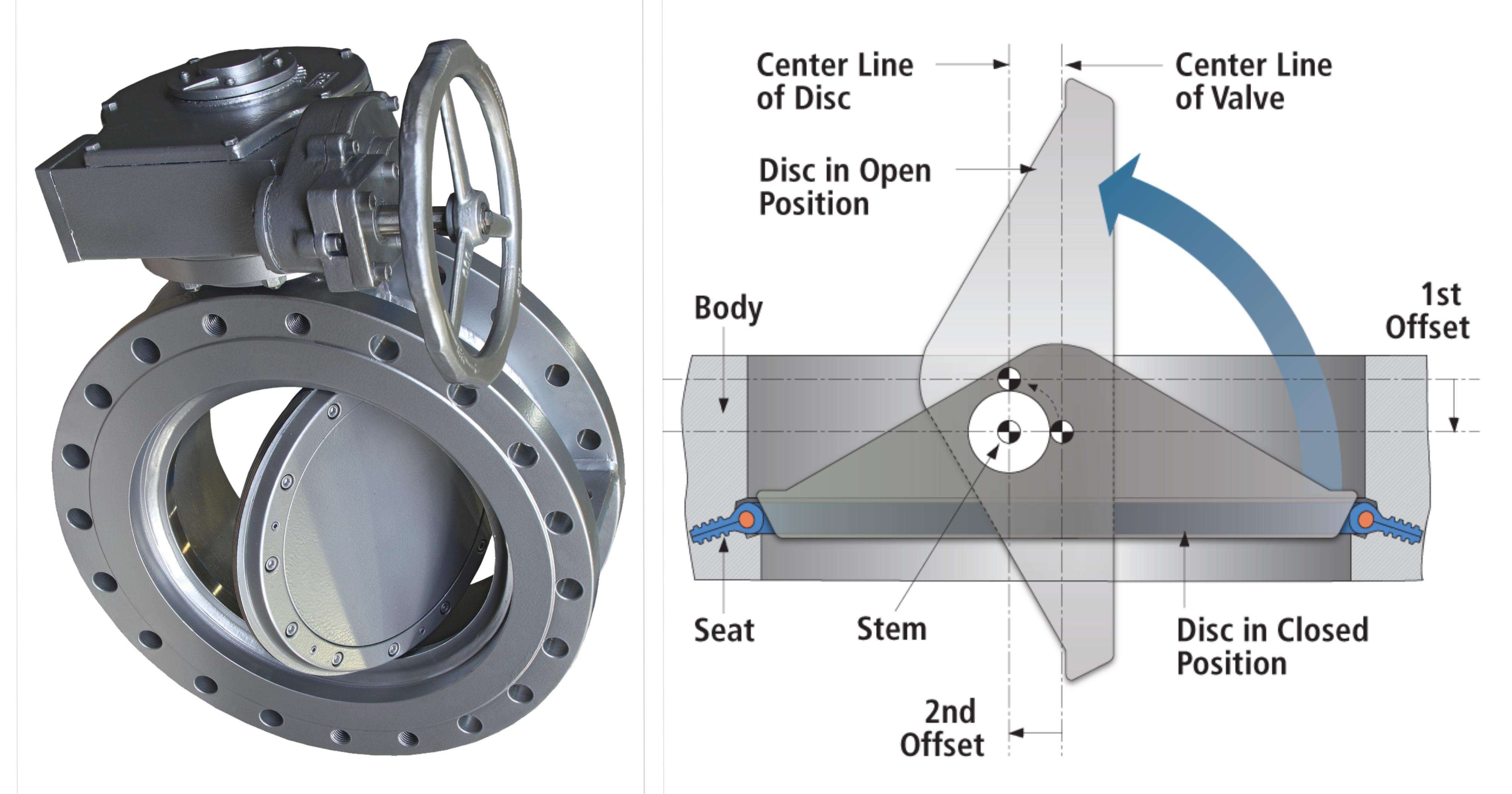

Low Emission Ball Valves

Adopting a rotating sphere to control flow, they have the advantage of quick opening and closing and are suitable for scenarios that require frequent operation. Advantages include:

Ease of operation: 90-degree rotation to fully open or close.

Low fluid resistance: Improves fluid efficiency and reduces energy consumption.

Compact: Saves installation space.

The disadvantages of ball valves are that they are difficult to use for precise flow control and are relatively expensive.

The final choice of valve depends on your specific application needs. For example, a low-discharge gate valve may be a better choice for a chemical process that requires precise flow control. For oil and gas pipelines that require quick on/off switching, a low-discharge ball valve would be more appropriate.

Low Emission Gate Valves in Sustainable Development

Traditional gate valves often lead to media leakage due to insufficient sealing performance, which not only causes waste of resources, but also may pollute the environment. Low emission gate valve adopts advanced sealing technology to effectively reduce the leakage rate, minimize fugitive emission, and help enterprises to achieve the goal of energy saving and emission reduction. The advantages of low emission gate valves are not only reflected in the environmental benefits, its excellent performance also brings economic benefits to enterprises. Lower leakage rates mean less maintenance costs, higher operating efficiency, and longer service life, ultimately helping companies to reduce operating costs and improve production efficiency. Choosing low emission gate valves is an important step for companies to practice the concept of sustainable development. It is not only responsible for the performance of the environment, but also a wise choice for enterprises to enhance competitiveness. Let us work together to empower green development with scientific and technological innovation, and contribute to the creation of a better future!

FAQs on Low Emission Gate Valves

Q: What are the effects of low emission gate valves on the environment?

A: By limiting the adverse effects on the environment through decreased gas leakage, low emission gate valves contribute to the reduction of greenhouse gas emissions and environmental pollution.

Q: How much does a low emission gate valve cost?

A: Although low emission gate valves usually cost a little more than traditional gates, their reduced gas leakage minimizes safety and environmental issues, which can result in long-term cost savings.

Q: What gases are low emission gate valves suitable for?

A: Low emission gate valves can be used for a wide variety of gases including, but not limited to, natural gas, hydrogen, oxygen, nitrogen, and more.

Q: Are low emission gate valves compatible with high temperature or high pressure environments?

A: Yes, some low emission gate valves are designed to withstand high temperatures and pressures for applications that operate under these conditions.

Q: How do low emission gate valves respond in an emergency?

A: In the event of an emergency, low emission gate valves are often equipped with an emergency shut-off device to quickly close the valve to prevent a leak.

Q: What are the safety approvals and standards for low emission gate valves?

A: Low emission gate valves are typically required to meet various international standards and certification requirements, such as API 624, ISO 15848, etc., to ensure their safety and reliability.

Want To Learn More? Click Here To View Product Details!

Request a Quote

Request a Quote